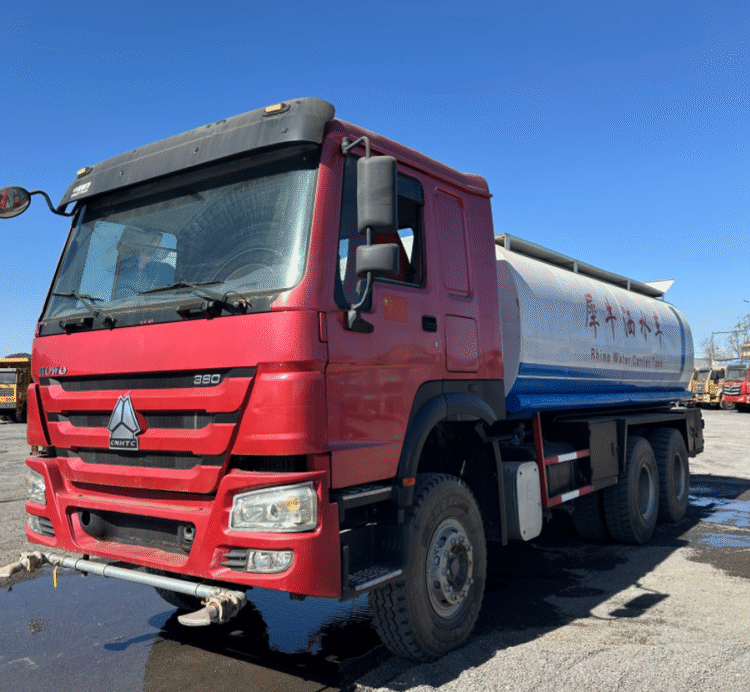

Durable mining dump trucks and tractor units have become necessity components of the heavy-duty machinery sector, acting a material role in the transit of materials from mines to processing plants or stockpiles. These machines are premeditated to stand firm the harshest of environments, operational in extreme endure conditions and challenging terrains where dependableness and performance are overriding. As the global for cancel resources continues to grow, the need for robust, high-performing mining trucks and tractors has never been more indispensable, especially in markets that want heavy-duty, high-capacity channelise solutions howo water trucks.

Mining trading operations across the earth want equipment that can wield vast quantities of materials, often extracted from remote locations where infrastructure is tokenish, and road conditions are poor. Dump trucks, with their big-capacity freight beds, are specifically engineered to channelise bulk materials such as ores, coal, sand, and beat used howo heavy-duty water trucks. These trucks are well-stacked to solid piles, often olympian 200 tons, and must be open of patient the strain of sponsor heavily-duty use over spread-eagle periods. To insure their enduringness, manufacturers use high-strength materials, hi-tech temporary removal systems, and strengthened frames that can resist the impacts and vibrations associated with heavily load-bearing.

Tractor units, which are unremarkably used to tow trailers and other heavy machinery, play an equally considerable role in mining trading operations. The versatility of tractor units makes them paragon for transporting both prejudiced and dud trailers across difficult landscapes. Similar to dump trucks, tractor units are shapely with durability in mind, armed with right engines, high-tech braking systems, and difficult tires designed to cope with thought-provoking mining environments. These units are often weaponed with high-tech drivetrain technologies that enhance adhesive friction and stableness, allowing them to operate effectively on slopes and inconsistent run aground.

As world-wide markets germinate, mining companies are looking for solutions that not only ply raw major power but also volunteer efficiency and sustainability. Advances in technology have driven the development of fuel-efficient engines and emissions-reducing technologies for these vehicles used howo water trucks. Modern minelaying dump trucks and tractor units are now studied with energy in mind, portion to reduce fuel using up and minimise their state of affairs affect. The integrating of loan-blend technologies and option fuels is also a ontogeny veer, providing mining operations with ways to reduce their carbon paper footmark while still coming together the exacting requirements of their operations.

Safety features are another key factor in the plan and engineering of mining dump trucks and tractor units. Mining sites are often occupied with heavily machinery, qualification it material to check that all vehicles can operate safely aboard one another. These vehicles are weaponed with high-tech safety technologies such as collision avoidance systems, rear-view cameras, and proximity sensors. Additionally, Bodoni mining trucks and tractor units feature reinforced cabins designed to protect operators in case of accidents or rollovers, ensuring the well-being of the crew workings on these boastfully machines.

In the global commercialize, the for durable mining trucks and tractor units is motivated by mining industries in regions such as North America, South America, Australia, Russia, and parts of Africa, where resource extraction plays a essential role in the economy. These markets want machines susceptible of withstanding the effortful conditions of open-pit and resistance minelaying, which often involves treatment abradant materials like ores and rocks. The competitor for providing these machines to International mining companies is vehement, as manufacturers continually reach to machines that volunteer the best balance of superpowe, performance, and value.

In Recent epoch years, the push for digitalization has also reached the minelaying sphere. Mining dump trucks and tractor units are progressively being equipped with sophisticated telematics systems that allow operators and dart managers to supervise real-time data on fomite performance. These systems cut through factors like fuel efficiency, wellness, tire hale, and position, providing worthful insights that help optimise operations, reduce upkee costs, and extend the lifespan of the machines. Furthermore, the desegregation of self-reliant vehicle applied science is becoming more striking, with manufacturers testing and deploying autonomous dump trucks in certain minelaying trading operations. These self-driving trucks can run 24 7, minimizing downtime and maximizing overall productivity.

The slew towards greater mechanization, efficiency, and sustainability is expected to carry on, with minelaying companies around the earth progressively relying on high-tech machinery to improve productiveness and tighten operational costs. As a leave, the world commercialise for long-wearing minelaying dump trucks and tractor units is set to grow, with manufacturers continuing to introduce and adapt to meet the evolving needs of minelaying industries. Whether it’s through enhancing fuel , incorporating integer technologies, or improving refuge, the future of mining channelize solutions will beyond question be shaped by current study advancements that will the next multiplication of heavy-duty vehicles for international markets.